Green hydrogen refers to hydrogen produced through a process that does not emit CO2 or other greenhouse gases into the atmosphere. Unlike traditional hydrogen production methods, which often rely on fossil fuels and contribute to pollution, green hydrogen is generated using renewable energy sources such as wind, solar, or hydroelectric power. This method of production ensures that the hydrogen is “clean,” making it an attractive option in the fight against climate change.

Why is green hydrogen important?

One of the primary reasons green hydrogen is crucial is its potential to reduce greenhouse gas emissions. As the world seeks to limit global warming and achieve net-zero emissions by mid-century, green hydrogen offers a way to decarbonize sectors that are difficult to electrify, such as heavy industry, aviation, and shipping.

It is also important for energy storage and grid stability. Renewable energy sources like wind and solar are intermittent, which means that they don’t produce energy all the time. Clean hydrogen can serve as a means of storing excess energy generated during periods of high production, which can then be used when production is low. This helps stabilize the energy grid and ensures a reliable supply of clean energy.

One advantage of hydrogen is its versatility as an energy carrier. It can be used to power fuel cells in vehicles, generate electricity, and serve as a raw material in various industrial processes.

How is green hydrogen produced?

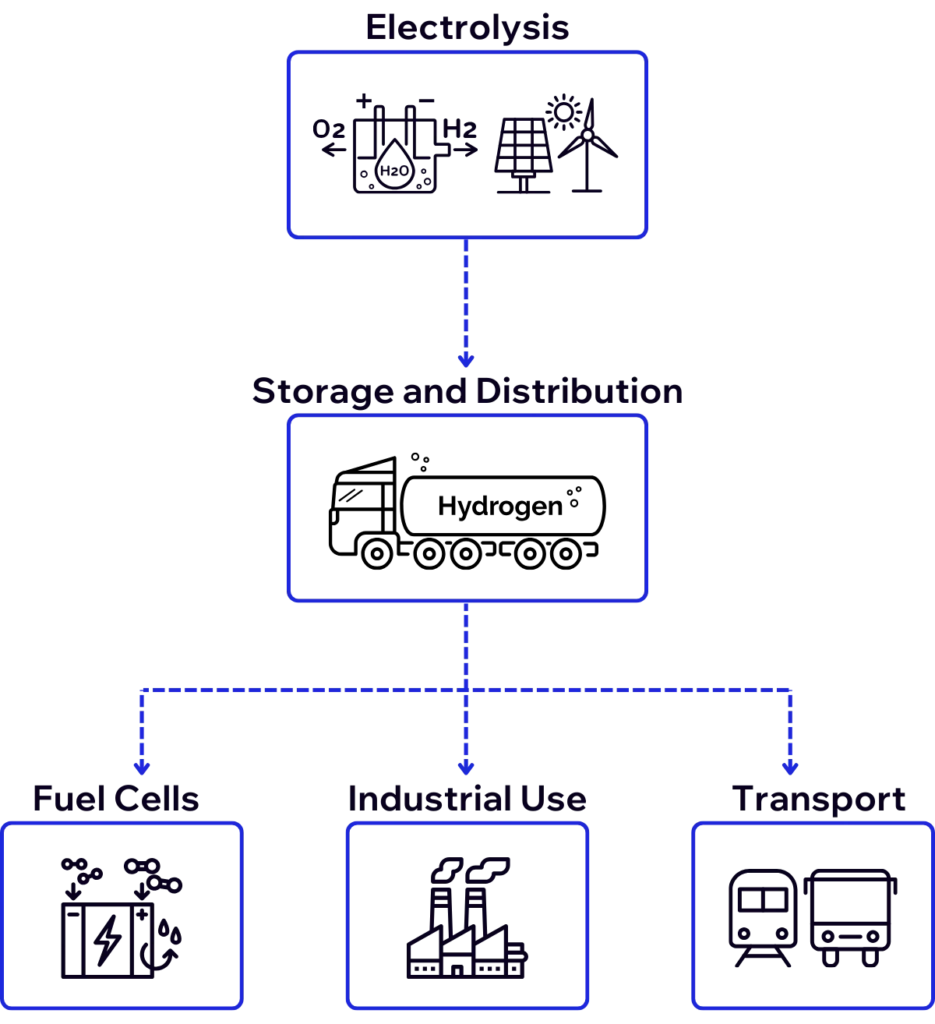

The process of producing green hydrogen typically involves the following steps:

1. Electrolysis: Green hydrogen is produced through a process called electrolysis, which involves splitting water (H₂O) into hydrogen (H₂) and oxygen (O₂) using an electric current. The key to making this process “green” is that the electricity used must come from renewable energy sources. When powered by wind, solar, or hydroelectric energy, the entire process is carbon-free.

2. Storage and Distribution: Once produced, hydrogen can be stored in various forms; gas, liquid, or even as part of chemical compounds. This stored hydrogen can then be transported via pipelines, trucks, or ships to where it is needed. It can also be stored in large quantities for later use, which is especially valuable for balancing supply and demand in the energy grid.

3. End Use: Green hydrogen can be utilized in multiple ways such as fuel cells, industrial processes and transport. The process of fuel cells for electricity generation combines hydrogen with oxygen in a chemical reaction that produces electricity, water, and heat, with no harmful emissions.

While hydrogen is already used in various industrial processes, such as refining petroleum and producing ammonia for fertilizers, the switch to clean hydrogen is crucial to make these processes more environmentally friendly.

Hydrogen fuel cell vehicles (FCVs) are an emerging technology that could replace traditional internal combustion engines, offering a zero-emission alternative for cars, buses, trucks, and even trains.

What are the disadvantages of green hydrogen?

Green hydrogen does hold immense potential as a cornerstone of a sustainable energy future, however, the industry is still in its early stages and faces several significant challenges. These hurdles must be addressed to unlock the full potential of green hydrogen and facilitate its widespread adoption.

High production costs

One of the most significant barriers to the development of green hydrogen is the high cost of production. Electrolysis, the process used to produce clean hydrogen, is currently more expensive than traditional hydrogen production methods, such as steam methane reforming (SMR), which relies on natural gas.

The cost disparity is largely due to the expensive electrolyzers needed for electrolysis and the relatively high cost of renewable electricity. While costs are expected to decrease as technology advances and economies of scale are realized, the current expense remains a substantial obstacle to scaling up green hydrogen production.

Infrastructure limitations

The infrastructure required to produce, store, transport, and utilize hydrogen is not yet fully developed. Unlike the well-established networks for fossil fuels, hydrogen infrastructure is in its infancy, with limited hydrogen refueling stations, pipelines, and storage facilities.

Building out this infrastructure will require substantial investment, careful planning, and coordination across multiple sectors. The lack of existing infrastructure makes it challenging to integrate green hydrogen into current energy systems and limits its immediate impact.

Energy efficiency concerns

The process of producing, transporting, and converting green hydrogen into usable energy is not entirely efficient. Electrolysis itself is energy-intensive, and there are losses associated with storing and transporting hydrogen. Additionally, converting hydrogen back into electricity using fuel cells or combustion involves further energy losses.

These efficiency challenges mean that, in some cases, using electricity directly (e.g., in battery electric vehicles or grid storage) may be more efficient than converting it into hydrogen and back again. Improving the overall energy efficiency of green hydrogen processes is crucial for its competitiveness as a clean energy solution.

Renewable energy availability

The production of green hydrogen relies entirely on the availability of renewable energy sources. However, in many parts of the world, the capacity to generate sufficient renewable energy is still limited. Regions that lack abundant wind, solar, or hydroelectric power may find it challenging to produce green hydrogen at scale.

Additionally, the fluctuating nature of renewable energy generation can lead to inconsistencies in hydrogen production, making it difficult to rely on green hydrogen as a stable energy source without significant storage solutions.

Regulatory and policy frameworks

The development of a robust green hydrogen industry also depends on supportive regulatory and policy frameworks. Currently, there is a lack of clear and consistent regulations and standards governing hydrogen production, distribution, and use. This regulatory uncertainty can deter investment and slow down the industry’s growth.

Governments and international bodies need to establish clear policies, provide incentives for green hydrogen projects, and create a level playing field with other clean energy technologies to encourage the industry’s development.

Market demand and commercial viability

The market for green hydrogen is still developing, and demand remains relatively low compared to more established energy sources. For green hydrogen to become commercially viable, there needs to be a significant increase in demand, driven by industries and sectors willing to invest in hydrogen technologies. Without sufficient demand, it will be challenging to justify the large-scale investments needed to build out the necessary infrastructure and bring down costs.

The difference between grey, pink, green and blue hydrogen

Grey, green, blue, and pink hydrogen refers to different methods of hydrogen production, each with varying energy sources and carbon footprints.

Grey Hydrogen

Grey hydrogen is produced from natural gas or methane through a process called Steam Methane Reforming (SMR). This method emits a significant amount of CO₂, making it the most carbon-intensive and least environmentally friendly option. Despite this, grey hydrogen is currently the most common and cheapest form of hydrogen production.

Grey hydrogen still dominates the global hydrogen market, making up the vast majority of production. Despite efforts to reduce reliance on carbon-intensive methods, grey hydrogen remains the cheapest and most widely available option. However, the focus on cleaner hydrogen alternatives is gradually shifting the attention and investment away from grey hydrogen, as stakeholders aim to decarbonize the energy sector.

Pink Hydrogen

Pink hydrogen is produced via electrolysis using electricity from nuclear power. While there are no direct carbon emissions during this production process, nuclear power presents its own environmental considerations, such as waste management. Pink hydrogen offers a steady and low-carbon power source for hydrogen production, especially in regions with established nuclear infrastructure.

While pink hydrogen remains a niche, interest is growing, especially in regions with established nuclear power infrastructure. Its role is becoming more relevant as countries look for stable, low-carbon options. Although it hasn’t reached the scale of blue or green hydrogen, there’s a recognition that pink hydrogen could play a larger role in the future, particularly as nuclear energy continues to be part of the decarbonization strategy.

Blue hydrogen

Blue hydrogen is also produced from natural gas, like grey hydrogen, using SMR but includes Carbon Capture and Storage (CCS) technology to capture and store the CO₂ emissions. This makes blue hydrogen less carbon-intensive than grey hydrogen, but it is not entirely carbon-neutral due to potential leaks or incomplete CO₂ capture. As a result, it is considered a transitional solution on the path to green hydrogen, balancing cleaner production with more affordable costs.

Blue hydrogen has gained traction as a transitional solution, with a significant increase in projects reaching the final investment decision (FID). Between 2020 and 2024, the number of committed clean hydrogen projects, which include blue hydrogen, surged from 102 to 434, representing an increase in investment from $10 billion to $75 billion. This growth is primarily due to carbon capture and storage (CCS) technologies becoming more integrated into hydrogen production processes, and the growing support from policy incentives, such as the U.S. 45Q tax credit.

Green hydrogen

As mentioned before, green hydrogen is created through electrolysis, where water is split into hydrogen and oxygen using renewable electricity sources like wind, solar, or hydropower. This process results in zero emissions, making green hydrogen the cleanest and most sustainable form. However, it is currently more expensive due to the cost of renewable electricity and electrolysis infrastructure.

Green hydrogen remains a small fraction of total global hydrogen production, accounting for less than 1% of the 97 million tonnes produced worldwide in 2023. Despite its limited share, there’s a clear trend toward expansion, driven by increased investments and a stronger push from governments to scale up renewable hydrogen infrastructure. However, high costs and infrastructure challenges still slow the scaling process. Progress is evident, but more investment and policy support are needed to make it truly mainstream.

Is green hydrogen really the future?

The International Energy Agency’s 2024 report emphasizes that governments and companies need to work together to increase investment and build the infrastructure necessary to make green hydrogen scalable and more cost-competitive.

This suggests that green hydrogen has the potential to be the future of energy if significant investment, regulatory support, and technological advancements are realized. This particularly applies to sectors where electrification alone isn’t feasible. Therefore, it might not be the only solution, but it’s increasingly seen as a vital component in the broader transition to a decarbonized energy system.

At Southern Lights, we know that green hydrogen is the future. That is why we have developed a software to help energy developers to start their green hydrogen journey.