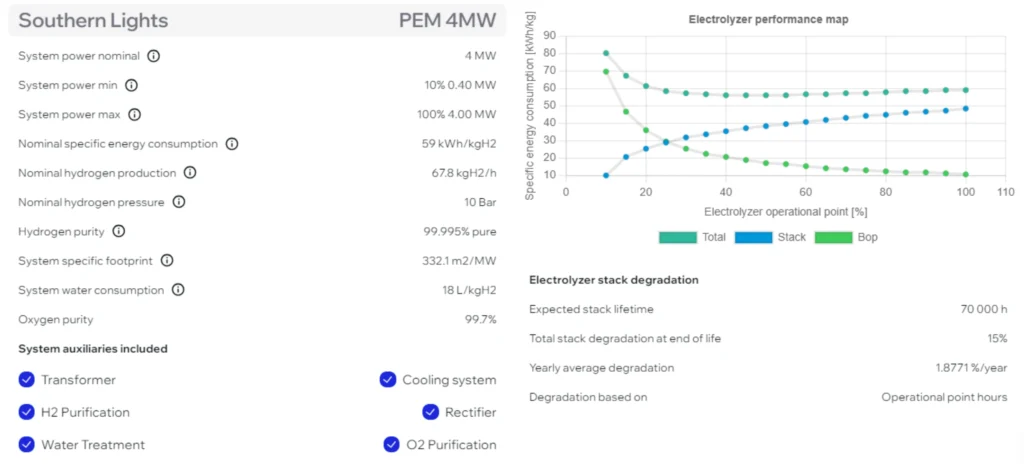

Here we will use the Southern Lights software to conduct a prefeasibility study for a green ammonia plant. Southern Lights facilitates and increases the accuracy when dealing with design, simulation, and optimization of Power-to-X projects, making the assessment process straightforward. Please note that this green ammonia production project is hypothetical and based on practical assumptions to ensure comprehensive coverage of the main steps when conducting a prefeasibility study with the help of Southern Lights.

Project overview

In the southernmost part of South America, at the tip of Patagonia, the Magallanes region of Chile offers a unique opportunity for sustainable energy projects due to its exceptional wind resources. This study explores the feasibility of establishing a green ammonia production plant in this region.

The primary goal of this project is to develop and finance a green ammonia production plant powered by hydrogen produced from wind energy. This green ammonia is crucial for decarbonizing the fertilizer industry and supporting emerging energy applications, with significant markets in Europe and Asia.

In this hypothetical study, a development opportunity has been identified by the origination team of an energy development company, to produce and export approximately 340 tons of ammonia per day, equivalent to 124,100 tons per year. The team has selected a site in the Magallanes region, which is advantageous due to its abundant wind resources and strategic proximity to the Strait of Magellan, a vital maritime route connecting the Pacific and Atlantic Oceans, further enhancing the project’s appeal for international exports.

To assess this project, a preliminary conceptual design was developed using the Southern Lights software. The design included:

- A Haber Bosch Plant: Capable of producing 450 tons of NH₃ per day

- An Electrolyzer Plant: Featuring a 400 MW electrolyzer capacity

- A Hydrogen Storage system: Capacity for 40 tons of compressed H2

- An Onshore Wind Plant: 434 MW capacity

The primary business model of the project is to sell green ammonia to international markets, such as Europe and Japan. Additionally, the surplus hydrogen, if any, is considered to be sold to the local gas distribution company for blending into the gas network.

Regarding the renewable fuel prices, the market price for green hydrogen is set at 2 [€/kg]¹. For ammonia, the sale price is 1.300 [€/ton]². If you are interested in learning more about the demand projections and price analysis for hydrogen and other renewable fuels, subscribe to our newsletter for coming articles on the topic.

Prefeasibility study scope and structure

This prefeasibility study addresses key questions for the business development team and management of the hypothetical energy development company behind the project. It follows a typical feasibility workflow used in solar and wind project development during greenfield stages and aims to demonstrate how this process can be internalized and streamlined using Southern Lights software.

The study evaluates various aspects of the project to determine its feasibility and potential benefits under different scenarios, including:

- Project Scope and Boundary Conditions: Project limits and extension definition.

- Key Infrastructure & Technical Design: Necessary infrastructure and technical specifi-cations outline.

- Cost Estimation: Project’s financial requirements.

- Results, Optimization & Business Analysis: Potential outcomes and business analysis.

- Conclusions: Findings summary and final recommendations.

By systematically addressing this outline, the prefeasibility study aims to provide a comprehensive assessment of the proposed green ammonia production plant’s viability and its contribution to sustainable energy solutions.

For the scope of this prefeasibility study, the cost for transportation will be considered as an exogenous variable associated with procuring the service with an external partner or a third party providing this part of the project. It is considered that the project will be able to connect to the required infrastructure to supply compressed hydrogen and ammonia via a price tag based on the levelized cost of the infrastructure.

Key infrastructure and design parameters

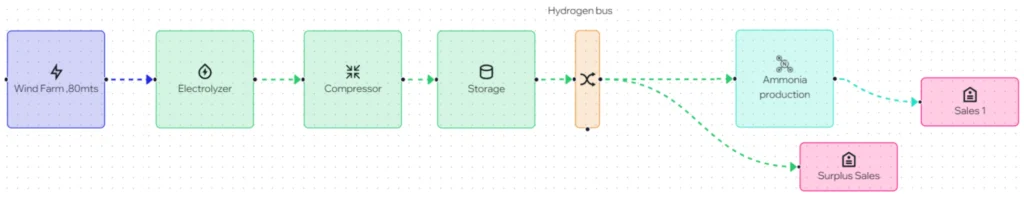

Based on the project’s commercial definitions, several scenarios were considered, each with varying design parameters such as installed electrolyzer capacity, electrolyzer technology, energy source, power plant capacity, and ammonia production capacity. After evaluating the techno-economic results of the different scenarios, only the case with the most promising results was selected for presentation in this article. In Figure 2 a diagram of the whole system is presented.

The system configuration includes the following components:

- Wind farm

- Desalinization and water treatment plant

- PEM electrolyzer plant

- Air separation unit

- Compression unit

- Hydrogen Storage tanks

- Haber-Bosch reactor

The optimal sizes for the components will be determined using the optimization tools included in the Southern Lights Software.

The goal is to produce at least 124.100 tons of ammonia per year, with the lowest LCOA possible.

Location

The Magallanes region, located in the southernmost part of Chile, boasts abundant wind resources, making it an ideal site for renewable energy projects. The proposed location is south of a small area called “La Portada,” characterized by its access to the Strait of Magellan, and exceptional wind potential. Figure 3 provides a satellite image featuring a heat map of the average wind speed across the region. Figure 4 highlights the site with a yellow polygon, indicating where the entire system could be installed.

Electricity

Due to the characteristics of the project in this prefeasibility study, a new wind farm is required. The plant size optimization will be addressed in a later section of the article. For the proposed location, a preliminary assessment indicates that the potential plant factor is 63.3%³.

These results were obtained based on historical databases and Wind Simulations tools. Figure 5 shows the variation in the capacity factor of the proposed system. Vestas V90-2.0 [MW] turbines were considered in the simulations.

Since the scope of this prefeasibility study is hydrogen and ammonia production, the wind farm will be considered an external asset, that provides renewable energy for a price of 35[€/MWh], which is based on an estimation of the LCOE that could be reached for these capacity factors and project scale in that location.

Water

The selected location can utilize surface water (rivers), groundwater (aquifers), and seawater from the Strait of Magellan for the plant. Based on preliminary simulations, the total water consumption is estimated to exceed 60 [m3/h]. Given this requirement, and the limited surface water availability, a desalination plant is required.

Electrolyzers require pretreated, demineralized, and deionized water to prevent equipment damage from impurities. Considering the preliminary electrolyzer production capacity, the maximum water consumption is 121 [ton/h] of demineralized water for hydrogen production.

For water treatment, the recommended process includes chemical pre-treatment for desalination (screening, grit removal, chlorination, coagulation-flocculation, flotation, and filtration) and demineralization using reverse osmosis and electro-deionization.

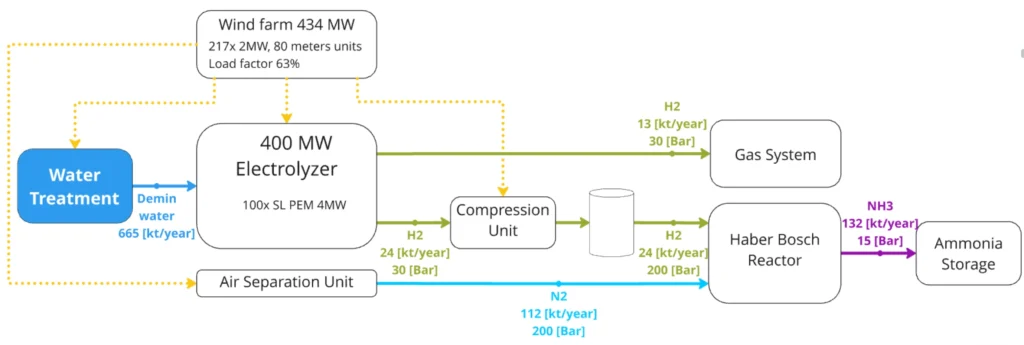

Tech selection

Proton Exchange Membrane (PEM) technology is recommended in this prefeasibility study, due to the high variability of the power source. However, if they reach commercial maturity at this scale, SOEC electrolyzers could also be considered. This rapidly evolving technology may offer better performance when combined with ammonia production.

The selected equipment for the simulations are a virtual 4MW model (Figure 6), from the Southern Lights Electrolyzer Database, that represents the standard characteristics of PEM alternatives in the current industry.

Cooling system

Due to the environmental conditions and the scope of this prefeasibility study, a dry cooling system was considered for the Electrolyzer and Haber-Bosch systems. These items will be included as part of the equipment investment for each module, as complementary systems.

These assumptions do not imply that future prefeasibility studies regarding the cooling system should not be carried out. The cooling system choice has an impact on the efficiency of the process affecting the energy consumption and on the operational costs of the project.

Ammonia Plant

The Haber-Bosch process synthesizes ammonia (NH₃) by reacting nitrogen (N₂) with hydrogen (H₂) under high pressure and temperature in the presence of a catalyst. The Air Separation Unit (ASU) is responsible for isolating nitrogen gas from the air, while a specific compressor increases the pressure of the hydrogen gas before it is supplied to the Haber-Bosch reactor.

In the reactor, a complex process synthesizes the ammonia. For further reading on the topic, we recommend the article “How Renewable Ammonia is Shaping a Sustainable Tomorrow”.

Summary of design parameters

The preliminary technical parameters considered for the project design, which include the electrolyzer, the compressor unit, the hydrogen storage system, the ASU, and the Haber-Bosh reactor, are presented in Table 1.

Cost estimation

Capital Expenditure (CAPEX) and Operational Expenditure (OPEX) costs were estimated using parametric values derived from international, trustworthy sources, as well as an internal Southern Lights database. The capital costs include the manufacture and supply of the listed equipment but also other significant expenditures such as transport infrastructure, installation, commissioning, and ancillary works.

On the other hand, OPEX items were grouped into different categories such as operation and maintenance, land lease, and energy consumption, among other operational cost.

In the present prefeasibility study, Class 5⁴ sources of information were used as input in the Southern Lights Platform, resulting in Class 5 results. It is most important to highlight that Southern Lights Software’s cost structure is flexible and allows the inclusion of Class 4 and Class 3 cost structures. In such cases, the results will maintain respective classifications as Class 4 and Class 3 studies.

Design optimization

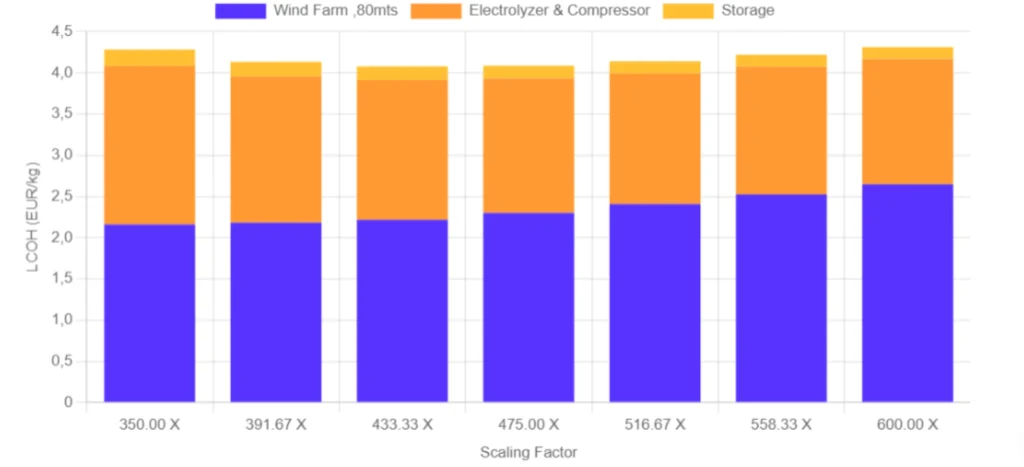

In a preliminary analysis, the wind farm size was optimized using the Southern Lights software. A specially designed tool in this software allows for running multiple simulations in parallel to evaluate the sensitivity of various KPIs. Figure 7 shows the variation in LCOH when assessing wind farm capacities between 350 MW and 600 MW.

By optimizing solely for LCOH, the determined optimal wind farm nominal power is 434 MW. This preliminary configuration provides as results an LCOH of 4.08 [€/kg] and 1.19[€/kg] for the LCOA.

Notice that, the analysis showed that the wind farm capacity that minimizes the LCOH does not match the capacity that minimizes the LCOA. This discrepancy is due to the significant influence of the production limit of the assets on these variables.

However, the whole project optimization in this prefeasibility study requires further iterations, where other variables need to be optimized. In this case, after running optimizing simulations for the electrolyzer nominal power, a second iteration of the wind farm capacity, and adjusting the ammonia production capacity, an overall substantial improvement was conceived.

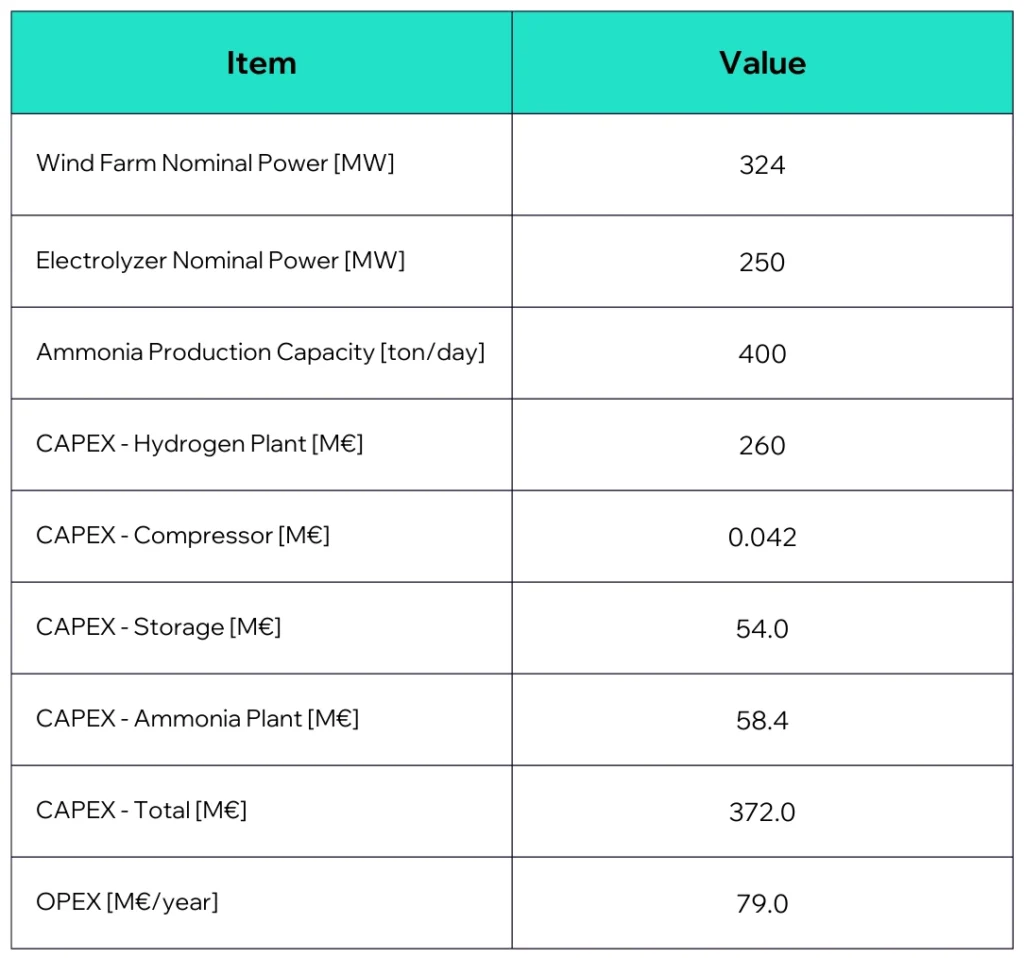

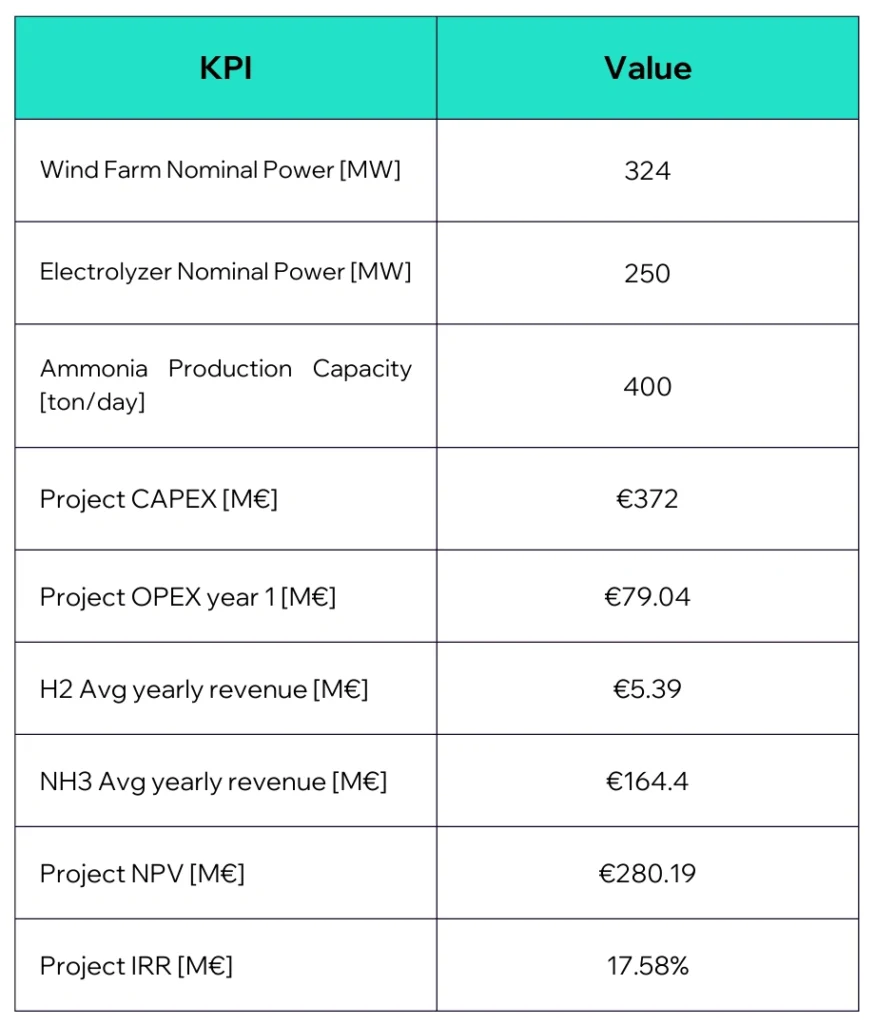

The main components optimal configuration considered a 324MW Wind Farm, a 250MW Electrolyzer, and a Haber-Bosch Reactor with production capacity of 400 [ton/day]. This new system complied with the ammonia production requirement and provides an LCOA of only 0.97[€/kg]. In the next section, these results and an extended analysis of them is presented.

Results and business analysis

The output of the simulation in the Southern Lights software for this prefeasibility study, includes the complete hourly system operation, throughout the entire defined lifecycle of the project (25 years). The software generates numerous charts and tables, presenting grouped data and various KPIs. Table 2 presents some key project parameters and the main cost results for the optimal configuration.

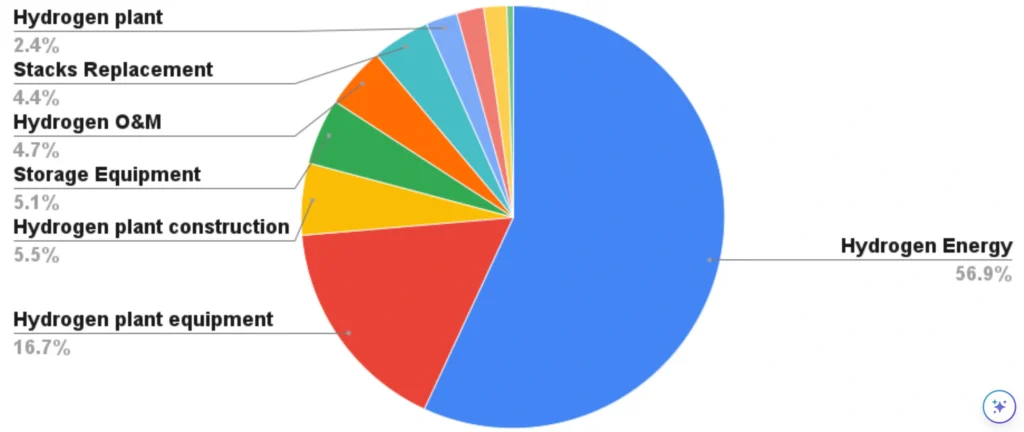

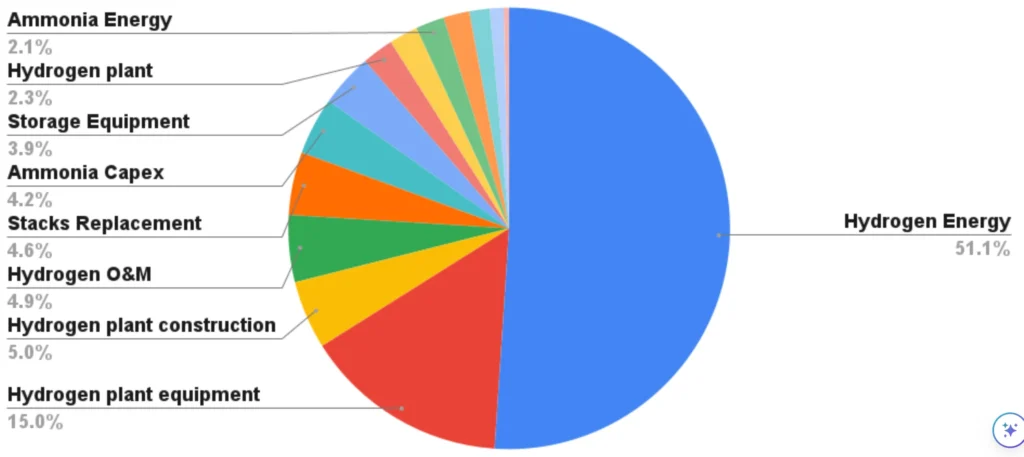

As part of the simulation result for the prefeasibility study, the determined LCOH is 4.22[€/kg], a bit higher than the original configuration. But, the LCOA decreased to 970 [€/ton]. Figure 8 illustrates the composition of the LCOH value, while Figure 9 details the LCOA.

For a complete view of the project’s tecno economic results, access the report provided by the Southern Lights software here.

Business performance

As mentioned at the beginning of the article, the business model includes selling the produced ammonia to international off-takers, such as Japan or the European Union. Additionally, surplus hydrogen production will be sold locally to the gas company for blending applications. The selling price has been set at 1,300 €/ton for ammonia and 2 €/kg for hydrogen.

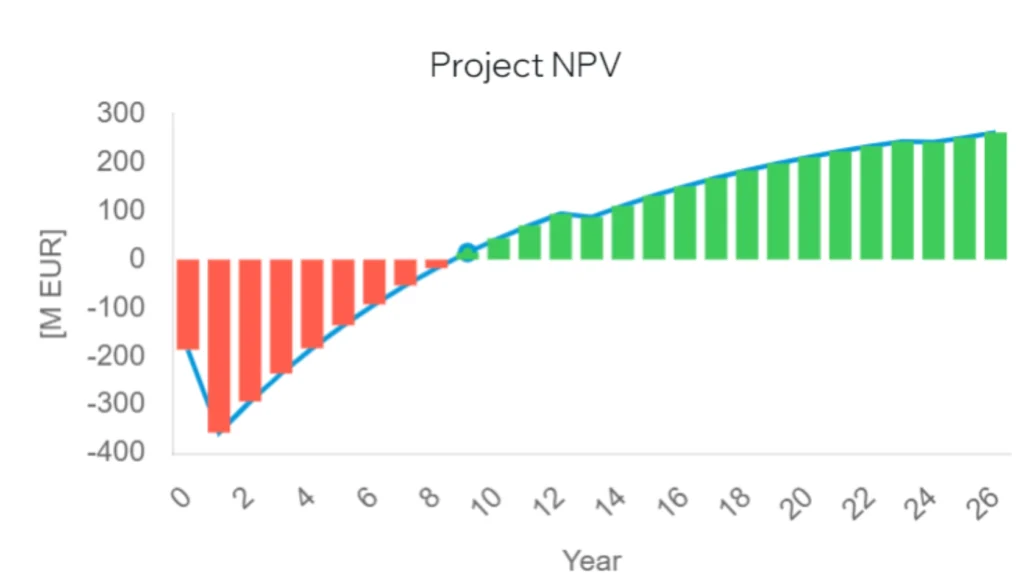

The economic and financial aspects were assessed using the business and financial modules of the Southern Lights software. Figure 10 shows the yearly cash flow throughout the project lifetime, while Figure 11 shows the net present value (NPV) evolution over the same period. Table 3 provides a summary of the main financial figures.

Based on these results, the project can be considered an attractive business opportunity. However, the defined ammonia selling price is considerably higher than the market price for gray alternatives(which can be as low as 400[€/ton]). Therefore, exploring options to reduce the levelized costs, or bridge the price gap is strongly recommended.

Several strategies could be considered to achieve this goal.

- Develop the project with a multi-stage plant:

- Reduce the specific cost of energy over time.

- Evaluate the ideal time to invest:

- Consider the cost projections for energy and CAPEX.

- Request public financial support:

- Utilize auctions or other mechanisms to gain financial aid.

Conclusion for this prefeasibility study

The prefeasibility study indicates that establishing a green ammonia production plant in the Magallanes region is both technically viable and economically promising. The integration of wind energy ensures a sustainable and renewable power source, while the use of advanced electrolysis and Haber-Bosch technologies can significantly reduce CO2 emissions compared to traditional methods.

Despite the current high production costs of green ammonia, projections suggest that advancements in technology and cost reductions could make it competitive by 2030.

The strong commitments to CO2 emissions reduction by potential off-takers in the European Union and Japan further enhance the project’s attractiveness. The study emphasizes the importance of addressing economic, regulatory, and resource barriers to ensure successful implementation and operation.

Key challenges include securing financing, obtaining necessary permits, and ensuring a reliable supply of renewable energy and water.