The electrolyzer is a critical component of green hydrogen production, and choosing the right one for your project is important. However, there are many parameters to take into account. In this article we’ll help you understand how to reason when doing your research, how you can find the best option for your project, and why a database of electrolyzers will help you on the way.

What to consider when choosing an electrolyzer

Requirements

First, you need to understand the specific requirements of your project, such as whether it will have energy supplied by the grid or from off-grid renewable energy sources.

This will define the relevance of the electrolyzer’s operational flexibility. If you’re integrating it with variable renewable energy sources, evaluate how well the electrolyzer can ramp up and down to match the fluctuating power supply.

Defining the energy source profile will help to narrow down which technology fits best to the project design. Since there are relevant performance differences between Alkaline, PEM, and Solid Oxide electrolyzers when operated on stable or dynamic regimes, understanding the pros and cons of each will help you identify the best fit for your specific project.

Costs

Next, you need to carefully estimate the costs involved. This includes not just the price of the electrolyzer stack itself, but also the additional Balance of Plant (BoP) and the installation costs. It’s easy to underestimate these extra expenses, so it’s crucial to get a full picture of the total capital expenditure.

Efficiency and degradation

Finally, you need to consider the efficiency and degradation. Look closely at the specific energy consumption, which measures how much electricity is required to produce a kilogram of hydrogen. Electrolyzers with higher efficiency will have lower operating costs in the long run. You also need to understand how the efficiency degrades over time, as this will impact the hydrogen production and the operation and maintenance plan.

Why timing matters

The timing of the decision-making process evolves throughout the different stages of a project’s development.

Early stage

In the early stages of a project, the focus should be on understanding the project’s requirements and constraints. This includes evaluating factors like the power profile, energy sources, and hydrogen offtake needs. At this stage, you should keep an open mind and explore various electrolyzer options without locking in on a specific technology or brand. The goal is to establish a solid understanding of the project’s premises and how different solutions may fit.

Prefeasibility stage

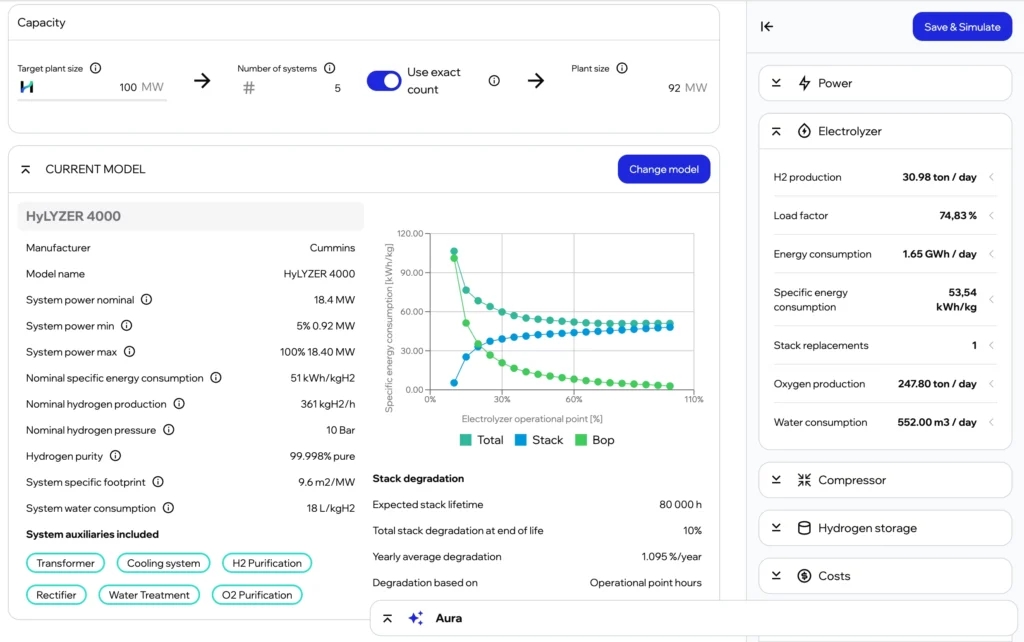

During the prefeasibility study stage, you should dive deeper into evaluating and comparing various scenarios. This involves using simulation tools, like Southern Lights, to model the performance and economics of different technologies, sizes, and operating conditions. The aim is to optimize the electrolyzer selection based on the project’s unique requirements and identify the most promising alternatives.

Pre-FEED and FEED

As the project progresses into the pre-FEED (front-end engineering and design) and FEED phases, the electrolyzer selection process becomes more refined. You will start engaging directly with manufacturers and EPC (engineering, procurement, and construction) companies to obtain detailed quotations, technical specifications, and performance guarantees. This allows you to shortlist the most viable options and understand the specific costs and capabilities associated with each.

The ultimate decision on the electrolyzer is typically made towards the end of the engineering phase, as the project approaches the final investment decision. However, the groundwork for this decision is laid much earlier through the process of evaluating different scenarios, gathering data from suppliers, and optimizing the system design.

Reading Tips: Optimization, simulation & financial modeling: How smart energy companies de-risk decisions and drive project success

Throughout this journey, you should maintain an open dialogue with manufacturers and even consider qualifying specific suppliers by visiting their facilities and assessing their delivery capabilities. This helps to build confidence in the selected technology and supplier, ensuring a smooth transition into the procurement and implementation phases of the project.

What to consider regarding prices of electrolyzers

First and foremost, it’s important to understand the overall cost structure of hydrogen production. Typically, the largest component of the costs, around 60-75%, comes from the energy input required to power the electrolyzer. This means that having access to low-cost electricity is crucial for minimizing production costs.

The remaining 25-40% of the costs are generally attributed to the capital expenditure (CAPEX), which includes the electrolyzer itself, as well as the associated Balance of Plant and whole system installation. This CAPEX is a significant factor, and you need to carefully evaluate the upfront costs of different electrolyzer models and technologies.

However, it’s not as simple as just choosing the cheapest option. The efficiency and degradation rate of the electrolyzer also play a major role. Even if a particular model has a lower upfront cost, if it is less efficient or degrades more quickly, it may end up costing more in the long run due to higher energy consumption and more frequent stack replacements. This is where the electrolyzer load factor becomes critical.

If the electrolyzer operates at a high capacity factor, the impact of the CAPEX on the overall hydrogen production costs can be minimized. But if the electrolyzer is underutilized, for example, due to intermittent renewable energy sources, the CAPEX burden becomes much more significant.

Common pitfalls when selecting electrolyzers

When it comes to selecting an electrolyzer, there are a few common pitfalls that you need to be aware of.

Deciding technology too early

There is a tendency to lock in on a specific technology or brand too early in the process. However, it’s important to maintain an open mind and explore the pros and cons of different options, as the optimal solution may not be immediately obvious. Each project has unique requirements, and the best-fit electrolyzer can vary depending on factors like the power profile, energy sources, and project scale.

Underestimating costs

Another common pitfall is the underestimation of costs. It’s easy to focus solely on the price of the electrolyzer stack itself, but project developers need to account for all the additional costs associated with the Balance of Plant and installation.

Systems such as water treatment, cooling, gas purification, and safety equipment can add significantly to the overall capital expenditure. Failing to consider these additional costs can lead to unrealistic budget projections and unexpected challenges down the line.

Trusting specifications

Furthermore, you should be cautious about relying too heavily on the technical specifications and performance claims made by manufacturers, especially when it comes to factors like degradation rates. While the data sheets may show impressive numbers, it’s important to dig deeper and understand the real-world warranties and guarantees that the manufacturers are willing to provide.

Discrepancies between the marketing claims and the actual performance guarantees can have a significant impact on the project’s long-term viability and profitability.

Reading Tips: Understanding the Offtaker: Why it matters in the green hydrogen market

Benefits of an electrolyzer database

Having access to a comprehensive and up-to-date database on electrolyzers can be incredibly valuable in the decision-making process. There are no widely available public databases that provide this level of detailed and organized information on the various electrolyzer models and their specifications.

However, Southern Lights has built an electrolyzer database that is accessible directly through the platform. This database consolidates information from a variety of sources, including publicly available data as well as proprietary data obtained through direct engagement with manufacturers.

The key advantage of the electrolyzer database in Southern Lights is that it presents the information in a structured and comparable format. Rather than having to scour through individual product datasheets and feasibility studies, you can easily access and compare the technical specifications, performance metrics, and cost estimates of different electrolyzer models all in one place.

Moreover, the database is regularly updated to reflect the latest market developments and changes in the market. This ensures that you have access to the most current and accurate information as you evaluate and select the optimal electrolyzer solution for your specific project requirements.

Beyond just providing the data, Southern Lights also allows you to simulate and model different scenarios. This enables you to test various assumptions, such as energy prices, utilization rates, and degradation, to understand the impact on the overall hydrogen production economics.